Solid Profile

Solid Profile heavy duty chains are the best choice for the highest demands on service life and performance.

Solid Profile chains are characterized by the special vertical link geometry, which enables to reduce the chain height even more than in the case of the double-flat chains. This makes it possible to reduce the height of the pan profile and to increase the loading capacity of the conveyor. The wide vertical links also have the largest contact surface with the pan sliding sheet and the contact surface between the horizontal and vertical chain links, which allows to significantly reduce the chain wear during operation, to decrease its elongation during operation and at the same time to minimize as much as possible the risk of its damage due to friction martensite. The chain geometry protects the links against jamming and, combined with a special heat treatment, the chain mechanical parameters exceed by more than 65% the requirements of the DIN 22255 standard. All the above-mentioned features make Solid Profile chains the first choice for the highest drive powers application and operation on the mining faces. FASING produces Solid Profile chains in a range of sizes with horizontal link diameter 38-60 mm.

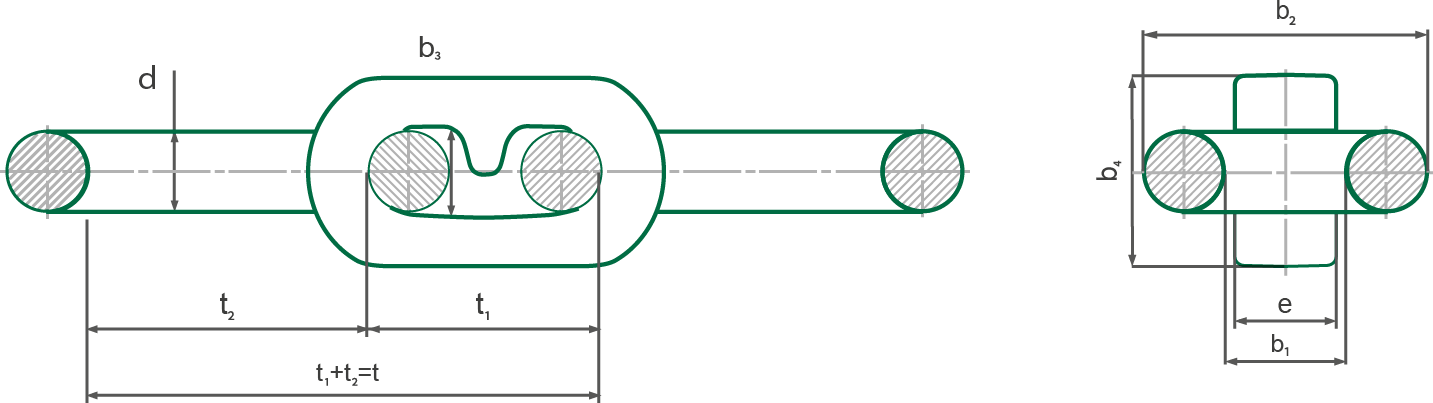

| Chain size d×t1 / t2 |

Bar diameter d |

Pitch t1+t2=t |

Round horizontal link |

Flat vertical link |

e max. |

~ Weight | ||

|---|---|---|---|---|---|---|---|---|

| b1 min. | b2 max. | b3 min. | b4 max. | |||||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/m] |

| 38 × 126/148 | 38 ± 1.1 | 126 + 148 = 274 ± 1.5 | 62 | 143 | 42 | 88 | 54 | 30.0 |

| 42 × 128/164 | 42 ± 1.1 | 126 + 164 = 292 ± 1.6 | 71 | 159 | 46 | 99 | 60 | 37.0 |

| 50 × 146/174 | 50 ± 1.5 | 146 + 174 = 320 ± 1.7 | 76 | 178 | 52 | 116 | 64 | 49.0 |

| 56 × 168/204 | 56 ± 1.6 | 168 + 240 = 372 ± 2.0 | 88 | 206 | 60 | 130 | 75 | 65.0 |

| Chain size d×t1 / t2 |

Chain grade | Test force | Breaking force min |

Unit elongation at test force max. |

Unit elongation at test breaking force min. |

Fatigue |

|---|---|---|---|---|---|---|

| [mm] | [kN] | [kN] | [%] | [%] | [cycles] | |

| 38 × 126/148 | C; DIN 22255 | 1 360 | 1 820 | 1.6 | 11 | 70 000 |

| C-PLUS | 1 930 | 70 000 | ||||

| SP | 1 950 | 70 000 | ||||

| PW-9 | 2 040 | 90 000 | ||||

| 42 × 128/164 | C; DIN 22255 | 1 660 | 2 220 | 1.6 | 11 | 70 000 |

| C-PLUS | 2 360 | 70 000 | ||||

| SP | 2 380 | 70 000 | ||||

| PW-9 | 2 500 | 90 000 | ||||

| 50 × 146/174 | C; DIN 22255 | 2 060 | 3 140 | 1.6 | 11 | 70 000 |

| C-PLUS | 3 340 | 70 000 | ||||

| SP | 3 400 | 70 000 | ||||

| PW-9 | 3 530 | 90 000 | ||||

| 56 × 168/204 | C; DIN 22255 | 2 600 | 3 940 | 1.6 | 11 | 70 000 |

| C-PLUS | 4 190 | 70 000 | ||||

| SP | 4 240 | 70 000 | ||||

| PW-9 | 4 430 | 90 000 |