Short link lifting chains

Marking

FAS – FASING

MAX – characterized with high hardness and made of manganese-nickel-molybdenum-chromium alloy steel with micro additives in compliance with DIN 17115 standard and FASING Technical Requirements

10 – strength grade ≥ 1 000 MPa

11 – strength grade ≥ 1 100 MPa

12 – strength grade ≥ 1 200 MPa

FAS MAX – FASING own marking

acc. to PAS 1061, ASTM A973/A973M and FASING Technical Requirements (grade 10, 11, 12)

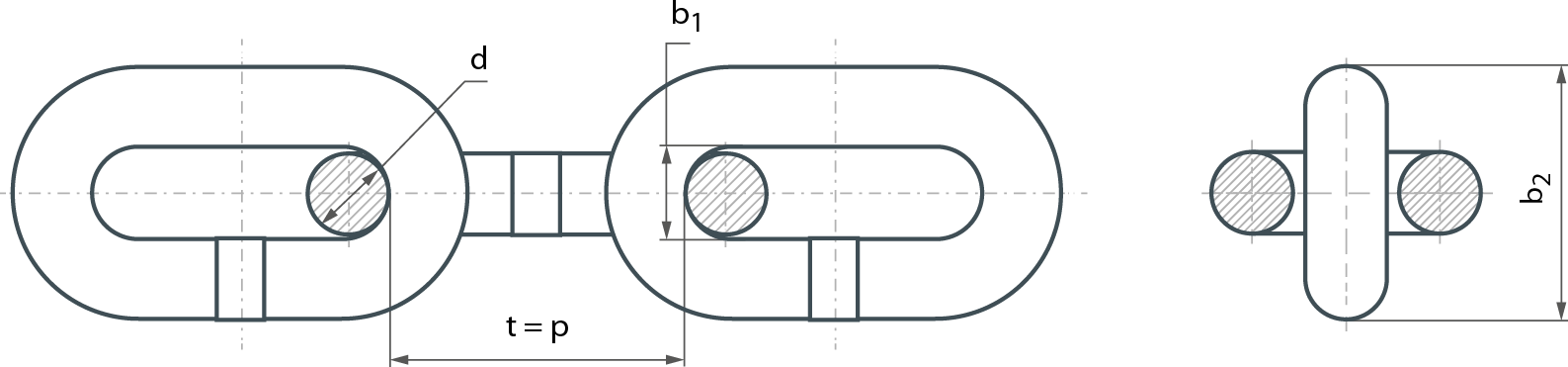

| Chain sized x t (p) | t=p | b1min. | b2 max. | Grade 10 • FAS MAX10 | Grade 11 • FAS MAX10 | Grade 12 • FAS MAX10 | ∼ Weight | ||||||

| Capacity | Testforce | Breakingforcemin. | Capacity | Testforce | Breakingforcemin. | Capacity | Testforce | Breakingforcemin. | |||||

| [mm] | [mm] | [mm] | [mm] | [t] | [[kN] | [[kN] | [t] | [[kN] | [[kN] | [t] | [[kN] | [[kN] | [kg/m] |

| 13×39 | 39±1.2 | 16.9 | 48.1 | 6.7 | 166 | 265 | 7.5 | 182 | 291 | 8.0 | 199 | 318 | 4.1 |

| 16×48 | 48±1.4 | 20.8 | 59.2 | 10.3 | 251 | 402 | 11.0 | 276 | 442 | 12.0 | 301 | 482 | 6.2 |

| 18×54 | 54±1.6 | 23.4 | 66.6 | 12.5 | 318 | 509 | 14.0 | 340 | 560 | 15.5 | 381 | 610 | 8.0 |

| 19×57 | 57±1.7 | 24.7 | 70.3 | 14.0 | 354 | 567 | 15.5 | 390 | 623 | 17.0 | 425 | 680 | 9.0 |

| 20×60 | 60±1.8 | 26.0 | 74.0 | 16.0 | 393 | 628 | 17.5 | 432 | 690 | 19.0 | 471 | 754 | 9.9 |

| 22×66 | 66±2.0 | 28.6 | 81.4 | 19.4 | 475 | 760 | 21.0 | 522 | 836 | 23.0 | 570 | 912 | 12.0 |

| 23×69 | 69±2.1 | 29.9 | 85.1 | 20.0 | 519 | 831 | 22.8 | 571 | 914 | 24.9 | 623 | 997 | 13.1 |

| 24×72 | 72±2.1 | 30.0 | 84.0 | 23.0 | 566 | 905 | 24.8 | 672 | 995 | 27.0 | 678 | 1085 | 14.5 |

| 25×75 | 75±2.2 | 32.5 | 92.5 | 25.0 | 614 | 982 | 27.0 | 675 | 1080 | 29.4 | 736 | 1176 | 15.6 |

| 26×78 | 78±2.3 | 33.8 | 96.2 | 26.5 | 664 | 1060 | 29.0 | 730 | 1168 | 31.8 | 796 | 1274 | 16.8 |

| 28×84 | 84±2.5 | 36.4 | 104.0 | 30.5 | 769 | 1230 | 34.0 | 846 | 1354 | 27.0 | 923 | 1477 | 19.5 |

| 30×90 | 90±2.7 | 37.5 | 105.0 | 35.5 | 884 | 1415 | 39.0 | 972 | 1554 | 42.5 | 1060 | 1696 | 22.1 |

| 32×96 | 96±2.9 | 41.6 | 118.0 | 40.5 | 1006 | 1610 | 44.0 | 1105 | 1768 | 48.0 | 1206 | 1929 | 25.4 |

| 36×108 | 108±3.2 | 46.8 | 133.0 | 50.0 | 1272 | 2035 | 56.0 | 1399 | 2238 | 61.0 | 1526 | 2442 | 32.1 |

| 38×114 | 114±3.4 | 49.4 | 140.6 | 56.5 | 1420 | 2270 | 62.5 | 1559 | 2494 | 68.0 | 1700 | 2720 | 35.8 |

| 40×120 | 120±4.0 | 52.0 | 148.0 | 62.5 | 1571 | 2515 | 69.0 | 1727 | 2763 | 75.5 | 1884 | 3014 | 39.7 |

| 45×135 | 135±4.0 | 58.5 | 167.0 | 81.0 | 1988 | 3180 | 87.5 | 2186 | 3498 | 95.5 | 2384 | 3815 | 52.2 |

| 48×144 | 144±4.3 | 62.4 | 177.6 | 92.0 | 2263 | 3620 | 99.5 | 2487 | 3980 | 108.5 | 2713 | 4341 | 57.2 |

| 50×150 | 150±4.5 | 65.0 | 185.0 | 98.0 | 2453 | 3925 | 108.0 | 2698 | 4318 | 118.0 | 2944 | 4710 | 62.0 |

| Total unit elongation at breaking force in a natural black state gr. 10 - min. 25%, gr. 11, 12 - min. 20%. |

Working Load Limit and Working Force (WLL, WF) should not exceed 25% of breaking force. |

Fatigue testing T = min. 20 000 cycles |

acc. to PN - EN 818 - 2 (grade 8)

| Grade 8 | |||||||

| Chain size d x t (p) |

t=p | b1 min. | b2 max. | Capacity | Test force |

Breaking force min. |

∼ Weight |

| [mm] | [mm] | [mm] | [mm] | [t] | [[kN] | [[kN] | [kg/m] |

| 13×39 | 39±1.2 | 16.9 | 48.1 | 5.3 | 133 | 212 | 4.1 |

| 16×48 | 48±1.4 | 20.8 | 59.2 | 8.0 | 201 | 322 | 6.2 |

| 18×54 | 54±1.6 | 23.4 | 66.6 | 10.0 | 254 | 407 | 8.0 |

| 19×57 | 57±1.7 | 24.7 | 70.3 | 11.2 | 284 | 454 | 9.0 |

| 20×60 | 60±1.8 | 26.0 | 74.0 | 12.5 | 314 | 503 | 9.9 |

| 22×66 | 66±2.0 | 28.6 | 81.4 | 15.0 | 380 | 608 | 12.0 |

| 23×69 | 69±2.1 | 29.9 | 85.1 | 16.0 | 415 | 665 | 13.1 |

| 24×72 | 72±2.1 | 30.0 | 84.0 | 18.0 | 452 | 723 | 14.5 |

| 25×75 | 75±2.3 | 32.5 | 92.5 | 20.0 | 491 | 785 | 15.6 |

| 26×78 | 78±2.3 | 33.8 | 96.2 | 21.2 | 531 | 850 | 16.8 |

| 28×84 | 84±2.5 | 36.4 | 104.0 | 25.0 | 616 | 985 | 19.5 |

| 30×90 | 90±2.7 | 37.5 | 105.0 | 28.0 | 706 | 1130 | 22.1 |

| 32×96 | 96±2.9 | 41.6 | 118.0 | 31.5 | 804 | 1290 | 25.4 |

| 36×108 | 108±3.2 | 46.8 | 133.0 | 40.0 | 1020 | 1630 | 32.1 |

| 38×114 | 114±3.4 | 49.4 | 140.6 | 45.0 | 1130 | 1810 | 35.8 |

| 40×120 | 120±4.0 | 52.0 | 148.0 | 50.0 | 1260 | 2010 | 39.7 |

| 45×135 | 135±4.0 | 58.5 | 167.0 | 63.0 | 1590 | 2540 | 52.2 |

| 48×144 | 144±4.3 | 62.4 | 177.6 | 72.0 | 1800 | 2890 | 57.2 |

| 50×150 | 150±4.5 | 65.0 | 185.0 | 78.5 | 1963 | 3140 | 62.0 |

| Total unit elongation at breaking force in a natural black state grade 8 - min. 20%. |

Working Load Limit and Working Force (WLL, WF) should not exceed 25% of breaking force. |

Fatigue testing T = min. 20 000 cycles Chain in grade 4 acc. to PN-EN 818-3 is available following the individual agreements with a customer. |

| Normal size | Single-leg | Two-leg | ||||||||||

| factor 1.0 | 0° < 45° factor 1.4 |

45°< 60° factor 1.0 |

||||||||||

| [mm] | gr.8 | gr.10 | gr.11 | gr.12 | gr.8 | gr.10 | gr. 11 | gr.12 | gr.8 | gr.10 | gr.11 | gr.12 |

| 13 | 5.3 | 6.5 | 7.5 | 8.0 | 7.5 | 9.1 | 10.5 | 11.2 | 5.3 | 6.5 | 7.5 | 8.0 |

| 16 | 8.0 | 10.3 | 11.0 | 12.0 | 11.2 | 14.4 | 15.4 | 16.8 | 8.0 | 10.3 | 11.0 | 12.0 |

| 18 | 10.0 | 12.5 | 14.0 | 15.5 | 14.0 | 17.5 | 19.6 | 21.7 | 10.0 | 12.5 | 14.0 | 15.5 |

| 19 | 11.2 | 14.0 | 15.5 | 17.0 | 16.0 | 19.6 | 21.7 | 23.8 | 11.2 | 14.0 | 15.5 | 17.0 |

| 20 | 12.5 | 16.0 | 17.5 | 19.0 | 17.0 | 22.4 | 24.5 | 26.6 | 12.5 | 16.0 | 17.5 | 19.0 |

| 22 | 15.0 | 19.4 | 21.0 | 23.0 | 21.2 | 27.1 | 29.4 | 32.2 | 15.0 | 19.4 | 21.0 | 23.0 |

| 26 | 21.2 | 26.5 | 29.0 | 31.8 | 30.0 | 37.1 | 40.6 | 44.5 | 21.2 | 26.5 | 29.0 | 31.8 |

| 28 | 25.0 | 30.5 | 34.0 | 37.0 | 33.5 | 42.7 | 47.6 | 51.8 | 25.0 | 30.5 | 34.0 | 37.0 |

| 30 | 28.0 | 35.5 | 39.0 | 42.5 | 39.2 | 49.7 | 54.6 | 59.5 | 28.0 | 35.5 | 39.0 | 42.5 |

| 32 | 31.5 | 40.0 | 44.0 | 48.0 | 45.0 | 56.0 | 61.6 | 67.2 | 31.5 | 40.0 | 44.0 | 48.0 |

| 36 | 40.0 | 50.0 | 56.0 | 61.0 | 56.0 | 70.0 | 61.6 | 85.4 | 40.0 | 50.0 | 56.0 | 61.0 |

| 38 | 45.0 | 56.5 | 62.5 | 68.0 | 63.0 | 78.4 | 78.4 | 95.2 | 45.0 | 56.5 | 62.5 | 68.0 |

| 40 | 50.0 | 62.5 | 69.0 | 75.5 | 70.0 | 87.5 | 96.6 | 105.7 | 50.0 | 62.5 | 69.0 | 75.5 |

| 45 | 63.0 | 81.0 | 87.5 | 95.5 | 88.2 | 113.4 | 122.5 | 133.7 | 63.0 | 81.0 | 87.5 | 95.5 |

| 50 | 78.5 | 98.0 | 108.0 | 118.0 | 109.9 | 137.2 | 151.2 | 165.2 | 78.5 | 98.0 | 108.0 | 118.0 |

| Normal size | Three-and four leg | Endless chain sling in choke hitch |

||||||||||

| 0° < 45° factor 2.1 |

45°< 60° |

factor 1.6 | ||||||||||

| [mm] | gr.8 | gr.10 | gr.11 | gr.12 | gr.8 | gr.10 | gr. 11 | gr.12 | gr.8 | gr.10 | gr.11 | gr.12 |

| 13 | 11.1 | 13.6 | 15.7 | 16.8 | 7.9 | 9.70 | 11.2 | 12.0 | 8.4 | 10.4 | 12.0 | 12.8 |

| 16 | 16.8 | 21.6 | 23.1 | 25.2 | 12.0 | 15.40 | 16.5 | 18.0 | 12.8 | 16.4 | 17.6 | 19.2 |

| 18 | 21.0 | 26.2 | 29.4 | 32.5 | 15.0 | 18.75 | 21.0 | 23.2 | 16.0 | 20.0 | 22.4 | 24.8 |

| 19 | 23.5 | 29.4 | 32.5 | 35.7 | 16.8 | 21.00 | 23.2 | 25.5 | 17.9 | 22.4 | 24.8 | 27.2 |

| 20 | 26.2 | 33.6 | 36.7 | 39.9 | 18.7 | 24.00 | 26.2 | 28.5 | 20.0 | 25.6 | 28.0 | 30.4 |

| 22 | 31.5 | 40.7 | 44.1 | 48.3 | 22.5 | 29.10 | 31.5 | 34.5 | 24.0 | 31.0 | 33.6 | 36.8 |

| 26 | 44.5 | 55.6 | 60.9 | 66.7 | 31.8 | 39.70 | 43.5 | 47.7 | 33.9 | 42.4 | 46.4 | 50.8 |

| 28 | 52.5 | 64.0 | 71.4 | 77.7 | 37.5 | 45.70 | 51.0 | 55.5 | 40.0 | 48.8 | 54.4 | 59.2 |

| 30 | 58.8 | 74.5 | 81.9 | 89.2 | 42.0 | 53.20 | 58.5 | 63.7 | 44.8 | 56.8 | 62.4 | 68.0 |

| 32 | 66.1 | 84.0 | 92.4 | 100.8 | 47.2 | 60.00 | 66.0 | 72.0 | 50.4 | 64.0 | 70.4 | 76.8 |

| 36 | 84.0 | 105.0 | 117.6 | 128.1 | 60.0 | 75.00 | 84.0 | 91.5 | 64.0 | 80.0 | 89.6 | 97.6 |

| 38 | 94.5 | 118.6 | 131.2 | 142.8 | 67.5 | 84.70 | 93.7 | 102.0 | 72.0 | 90.4 | 100.0 | 108.8 |

| 40 | 105.0 | 131.2 | 144.9 | 158.5 | 75.0 | 93.70 | 103.5 | 113.2 | 80.0 | 100.0 | 110.4 | 120.8 |

| 45 | 132.3 | 170.1 | 183.7 | 200.5 | 94.5 | 121.50 | 131.2 | 143.2 | 100.8 | 129.6 | 140.0 | 152.8 |

| 50 | 164.8 | 205.8 | 226.8 | 247.8 | 117.7 | 147.00 | 162.0 | 177.0 | 125.6 | 156.8 | 172.8 | 188.8 |

| Temperature t [C°] | |||

| -40<t<200 100% |

200<t<300 90% |

300<t<400 75% |

t<400 not allowed |