Double flat mining chains Master Profile

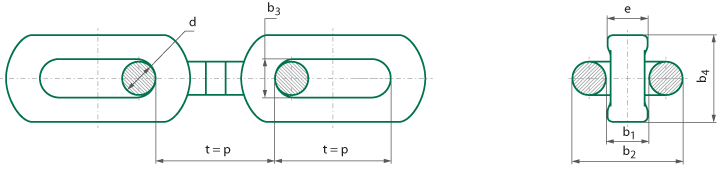

Master Profile double flat chains have all the advantages of flat chains produced acc. to DIN 22255. Moreover, they are characterized by even smaller vertical link height, which allows to increase the distance between conveyor metal sliding sheet and the pans. For this reason, the risk of friction martensite and the following performance failure is minimized. At the same time, the flight bar durability is extended as its permitted wear degree of higher value does not affect chain vertical links. The vertical links in a double flat chain are of the same height as round links made acc. to DIN 22252 standard, which are twice as smaller in diameter as for example double flat link chain 42×146-109 of height b4 = max 109 which corresponds to round link height 34×126, b2 = max 110.

Chain performance durability has been also improved thanks to special geometry achieved by computer simulations, which allowed for strengthening the critical areas and increase the size of a flat surface which rubs against the metal sliding sheet. It reduces the unit pressure in comparison to round link chains. Double flat link chains cooperate with the standard sprockets acc. to DIN 22256, flight bars acc. to DIN 22257 and locks acc. to DIN 22253 / PN-G-46696 - the chains may replace currently used round or flat link chains acc. to DIN 22255.

For the grades that differ in mechanical properties and sizes in comparison to the ones provided in DIN 22255 standard, FASING has developed its own Technical Requirements.

FASING has introduced double flat link chains 22×86-61 and 24×86-64 into production and sales. They are manufactured on the basis of DIN 22255 standard and FASING Technical Requirements.

The products have been awarded with:

· The Innovative Product – Katowice 2015, Katowice 2017, Katowice 2019

· Mining Success of the Year 2015 in the category “INNOVATION”, Katowice 2015

· The highest quality product for Double flat mining link chain FASING 22×86-61 and 24×86-64, Katowice 2019

| Chain size d×t (p) |

Bar diameter d |

Pitch t=p |

Round horizontal link |

Flat vertical link |

e max. |

~ Weight | ||

|---|---|---|---|---|---|---|---|---|

| b1 min. | b2 max. | b3 min. | b4 max. | |||||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/m] |

| 22 × 86 -61 | 22 ± 0.7 | 86 ± 0.8 | 27.0 | 74.0 | 26 | 61 | 26.0 | 9.9 |

| 24 × 86 -64 | 24 ± 0.7 | 86 ± 0.8 | 30.8 | 81.3 | 28 | 64 | 28.0 | 12.2 |

| 26 × 92 -70 | 26 ± 0.8 | 92 ± 0.9 | 30.1 | 87.0 | 30 | 70 | 30.0 | 13.7 |

| 30 × 108 - 80 | 30 ± 0.9 | 108 ± 1.1 | 34.1 | 99.0 | 34 | 80 | 34.0 | 17.7 |

| 34 × 126 - 84 | 34 ± 1.0 | 126 ± 1.3 | 39.0 | 111.0 | 38 | 84 | 38.0 | 22.7 |

| 34 × 126 - 94 | 34 ± 1.0 | 126 ± 1.3 | 38.1 | 111.0 | 38 | 94 | 38.0 | 22.7 |

| 38 × 126 - 101 | 38 ± 1.1 | 126 ± 1.3 | 42.1 | 123.0 | 42 | 101 | 42.0 | 30.1 |

| 38 × 137 - 101 | 38 ± 1.1 | 137 ± 1.4 | 42.1 | 123.0 | 42 | 101 | 42.0 | 29.0 |

| 42 × 146 - 109 | 42 ± 1.1 | 146 ± 1.5 | 48.6 | 139.0 | 46 | 109 | 48.5 | 36.0 |

| 48 × 152 - 115 | 48 ± 1.4 | 152 ± 1.5 | 64.0 | 163.0 | 52 | 115 | 58.0 | 47,0 |

| 48 × 152 - 121 | 48 ± 1.4 | 152 ± 1.5 | 62.0 | 163.0 | 52 | 121 | 53.0 | 47,0 |

| 48 × 144/160 | 48 ± 1.4 | 160 ± 1.6/144 ± 1.5 | 62.0 | 163.0 | 52 | 115 | 57.0 | 48,0 |

| 52 × 170 - 128 | 52 ± 1.9 | 170 ± 1.7 | 65.0 | 177.0 | 54 | 128 | 64.0 | 53.3 |

| 56 × 187 - 132 | 56 ± 1.9 | 187 ± 1.9 | 70.0 | 189.0 | 60 | 132 | 65.0 | 62.0 |

| 60 × 181/197 | 60 ± 1.9 | 197 ± 2.0/181 ± 1,8 | 72.0 | 198.0 | 63 | 136 | 70.0 | 71.0 |

| Chain size d×p |

Chain grade | Measuring force |

Test force | Breaking force min. | Unit elongation at test force max |

Unit elongation at breaking force min. |

Fatigue resistance min. |

|---|---|---|---|---|---|---|---|

| [mm] | [kN] | [kN] | [kN] | [%] | [%] | [cycles] | |

| 22 × 86 - 61 | C; DIN 22255 | 19 | 456 | 608 | 1.6 | 14 | 70 000 |

| C-PLUS | 456 | 646 | 70 000 | ||||

| C-SUPER | 490 | 680 | 70 000 | ||||

| PW-9 | 456 | 680 | 90 000 | ||||

| D | 530 | 760 | 1.4 | 11 | 90 000 | ||

| D-3 | 530 | 760 | 120 000 | ||||

| D-3 EXTRA | 530 | 800 | 90 000 | ||||

| E-FASING | 530 | 840 | 90 000 | ||||

| 24 × 86 -64 | C; DIN 22255 | 23 | 543 | 724 | 1.6 | 14 | 70 000 |

| C-PLUS | 543 | 769 | 70 000 | ||||

| C-SUPER | 580 | 815 | 70 000 | ||||

| PW=9 | 543 | 815 | 90 000 | ||||

| D | 630 | 900 | 1.4 | 11 | 90 000 | ||

| D-3 | 630 | 900 | 120 000 | ||||

| D-3 EXTRA | 630 | 950 | 90 000 | ||||

| E-FASING | 630 | 995 | 90 000 | ||||

| 22 × 92 - 70 | C; DIN 22255 | 26 | 637 | 850 | 1.6 | 11 | 70 000 |

| C-PLUS | 637 | 903 | 14 | 70 000 | |||

| C-SUPER | 700 | 970 | 70 000 | ||||

| PW-9 | 640 | 960 | 90 000 | ||||

| D | 740 | 1 060 | 1.4 | 11 | 90 000 | ||

| D-3 | 740 | 1 060 | 120 000 | ||||

| D-3 EXTRA | 740 | 1 115 | 90 000 | ||||

| E-FASING | 740 | 1 170 | 90 000 | ||||

|

30 × 108 |

C; DIN 22255 | 35 | 848 | 1 130 | 1.6 | 11 | 70 000 |

| C-PLUS | 848 | 1 202 | 14 | 70 000 | |||

| C-SUPER | 950 | 1 280 | 70 000 | ||||

| PW-9 | 850 | 1 270 | 90 000 | ||||

| D | 990 | 1 400 | 1.4 | 11 | 90 000 | ||

| D-3 | 990 | 1 400 | 120 000 | ||||

| D-3 EXTRA | 990 | 1 490 | 90 000 | ||||

| E-FASING | 990 | 1 555 | 90 000 | ||||

|

34 × 126

|

C; DIN 22255 | 45 | 1 090 | 1 450 | 1.6 | 11 | 70 000 |

| C-PLUS | 1 090 | 1 543 | 14 | 70 000 | |||

| C-SUPER | 1 200 | 1 650 | 70 000 | ||||

| PW-9 | 1 090 | 1 640 | 90 000 | ||||

| D | 1 270 | 1 800 | 1.4 | 11 | 90 000 | ||

| D-3 | 1 270 | 1 800 | 120 000 | ||||

| D-3 EXTRA | 1 270 | 1 910 | 90 000 | ||||

| E-FASING | 1 270 | 2 000 | 90 000 | ||||

| 34 × 126 - 84 | C; DIN 22255 | 45 | 1 090 | 1 450 | 1.6 | 11 | 70 000 |

| C-PLUS | 1 090 | 1 540 | 70 000 | ||||

| C-SUPER | 1 200 | 1 640 | 1.2 | 70 000 | |||

| PW-9 | 1 090 | 1 640 | 90 000 | ||||

|

38 × 126 |

C; DIN 22255 | 57 | 1 360 | 1 820 | 1.6 | 11 | 70 000 |

| C-PLUS | 1 360 | 1 930 | 14 | 70 000 | |||

| C-SUPER | 1 500 | 2 040 | 70 000 | ||||

| PW-9 | 1 360 | 2 040 | 90 000 | ||||

| D | 1 590 | 2 270 | 1.4 | 11 | 90 000 | ||

| D-3 | 1 590 | 2 270 | 120 000 | ||||

| D-3 EXTRA | 1 590 | 2 380 | 90 000 | ||||

| E-FASING | 1 590 | 2 495 | 90 000 | ||||

|

42 × 146 |

C; DIN 22255 | 69 | 1 660 | 2 220 | 1.6 | 11 | 70 000 |

| C-PLUS | 1 660 | 2 355 | 14 | 70 000 | |||

| C-SUPER | 1 800 | 2 500 | 70 000 | ||||

| PW-9 | 1 660 | 2 500 | 90 000 | ||||

| D | 1 940 | 2 770 | 1.4 | 11 | 90 000 | ||

| D-3 | 1 940 | 2 770 | 120 000 | ||||

| D-3 EXTRA | 1 940 | 2 910 | 90 000 | ||||

| E-FASING | 1 940 | 3 050 | 90 000 | ||||

|

48 × 152 |

C; DIN 22255 | 90 | 1 900 | 2 900 | 1.6 | 11 | 70 000 |

| C-PLUS | 1 900 | 3 075 | 14 | 70 000 | |||

| C-SUPER | 2 350 | 3 255 | 70 000 | ||||

| PW-9 | 2 170 | 3 255 | 90 000 | ||||

| D | 2 530 | 3 600 | 1.4 | 11 | 90 000 | ||

| D-3 | 2 530 | 3 600 | 120 000 | ||||

| D-3 EXTRA | 2 530 | 3 800 | 90 000 | ||||

| E-FASING | 2 530 | 3 980 | 90 000 | ||||

| 52 × 170 -128 | C; DIN 22255 | 106 | 2 210 | 3 400 | 1.2 | 11 | 70 000 |

| C-PLUS | 2 210 | 3 600 | 70 000 | ||||

| C-SUPER | 2 450 | 3 820 | 1.6 | 70 000 | |||

| PW-9 | 2 210 | 3 820 | 1.2 | 90 000 | |||

| D | 2 640 | 4 250 | 1.6 | 90 000 | |||

| D-3 | 2 640 | 4 250 | 120 000 | ||||

| 56 × 187 -132 | C; DIN 22255 | 123 | 2 610 | 3 960 | 1.2 | 11 | 70 000 |

| C-PLUS | 2 610 | 4 190 | 70 000 | ||||

| C-SUPER | 2 880 | 4 400 | 1.6 | 70 000 | |||

| PW-9 | 2 610 | 4 400 | 1.2 | 90 000 | |||

| D | 3 000 | 4 900 | 1.6 | 90 000 | |||

| D-3 | 3 000 | 4 900 | 120 000 | ||||

| 60 × 181/197 -136 | C; DIN 22255 | 141 | 3 000 | 4 520 | 1.2 | 11 | 70 000 |

| C-PLUS | 3 000 | 4 800 | 70 000 | ||||

| C-SUPER | 3 400 | 5 100 | 1.6 | 70 000 | |||

| PW-9 | 3 000 | 5 100 | 1.2 | 90 000 | |||

| D | 3 500 | 5 650 | 1.6 | 90 000 | |||

| D-3 | 3 500 | 5 650 | 120 000 | ||||